- HOME PAGE

-

PRODUCT CENTER

- Antistatic rubber mat

- Antistatic clothing

- Antistatic shoes

- Antistatic cap

- Apron Work package glove shoe cover Sleeve

- Anti static wrist strap grounding wire assembly

- Clean cotton swabs with dust-free rags and pape

- Antistatic chair antistatic turnover box

- Anti-static shielding bag

- Antistatic instruments and test equipment

- HONORARY QUALIFICATION

- ENTER Yiyuan

- SERVICE COMMITMENT

- NEWS

- CONTACT US

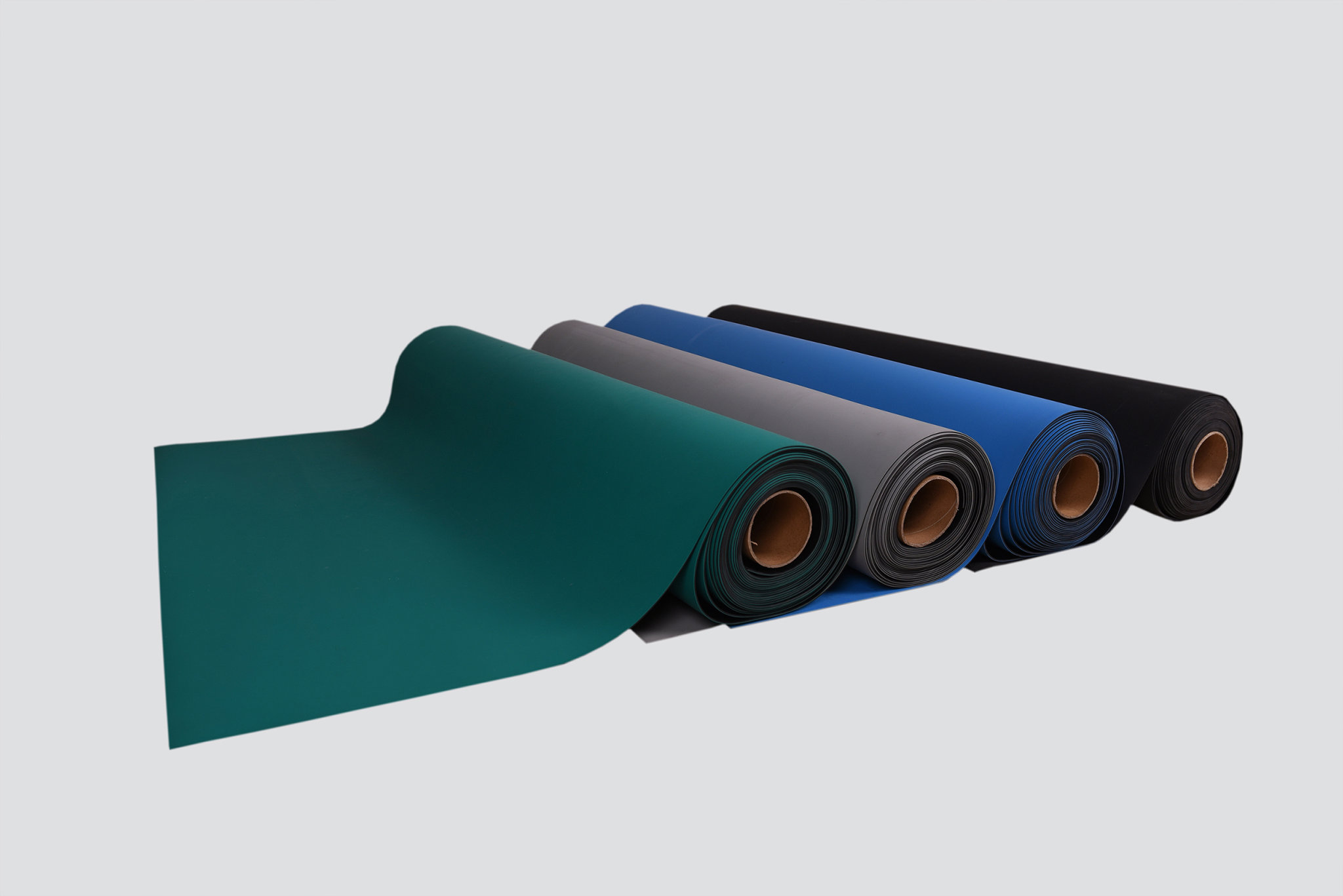

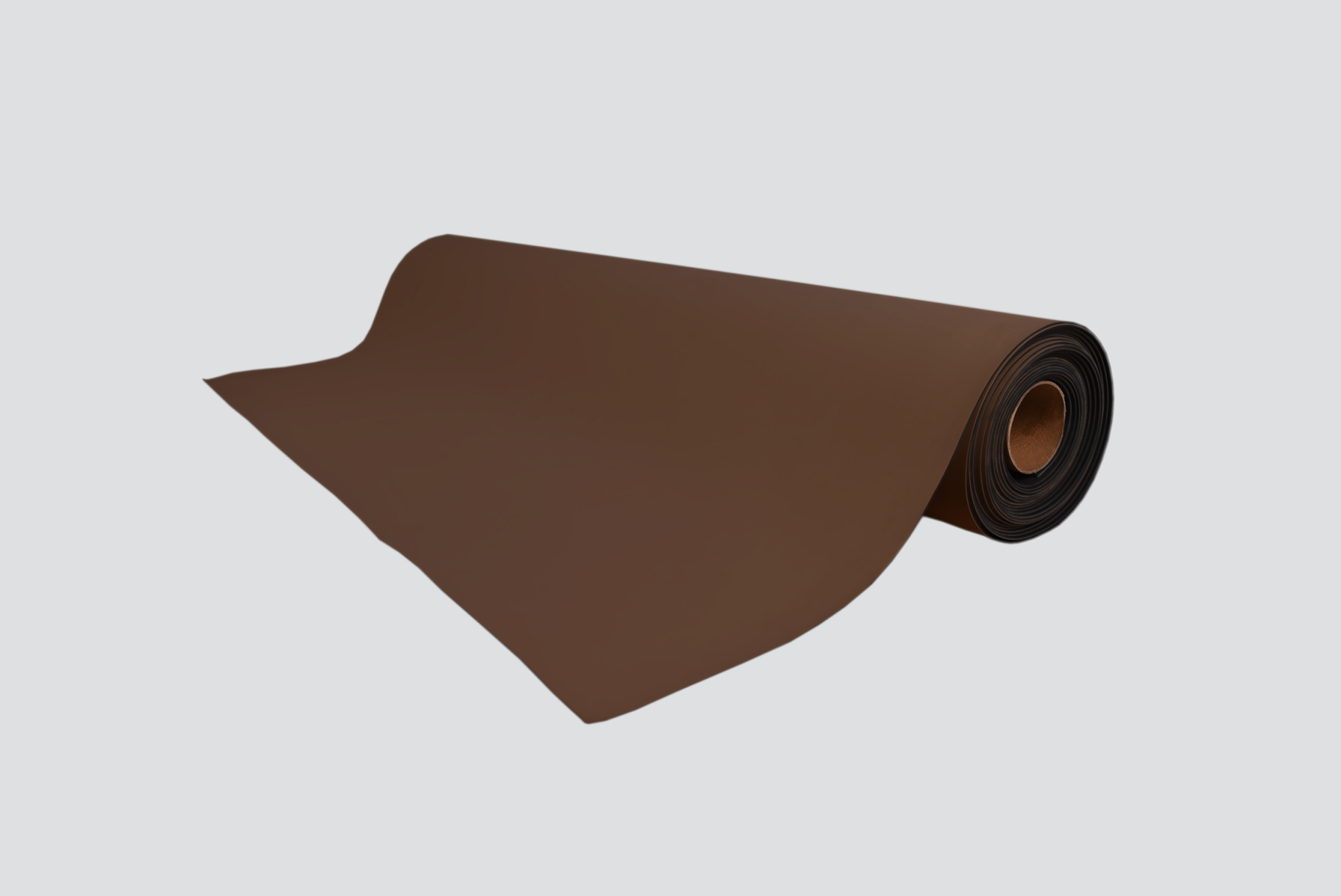

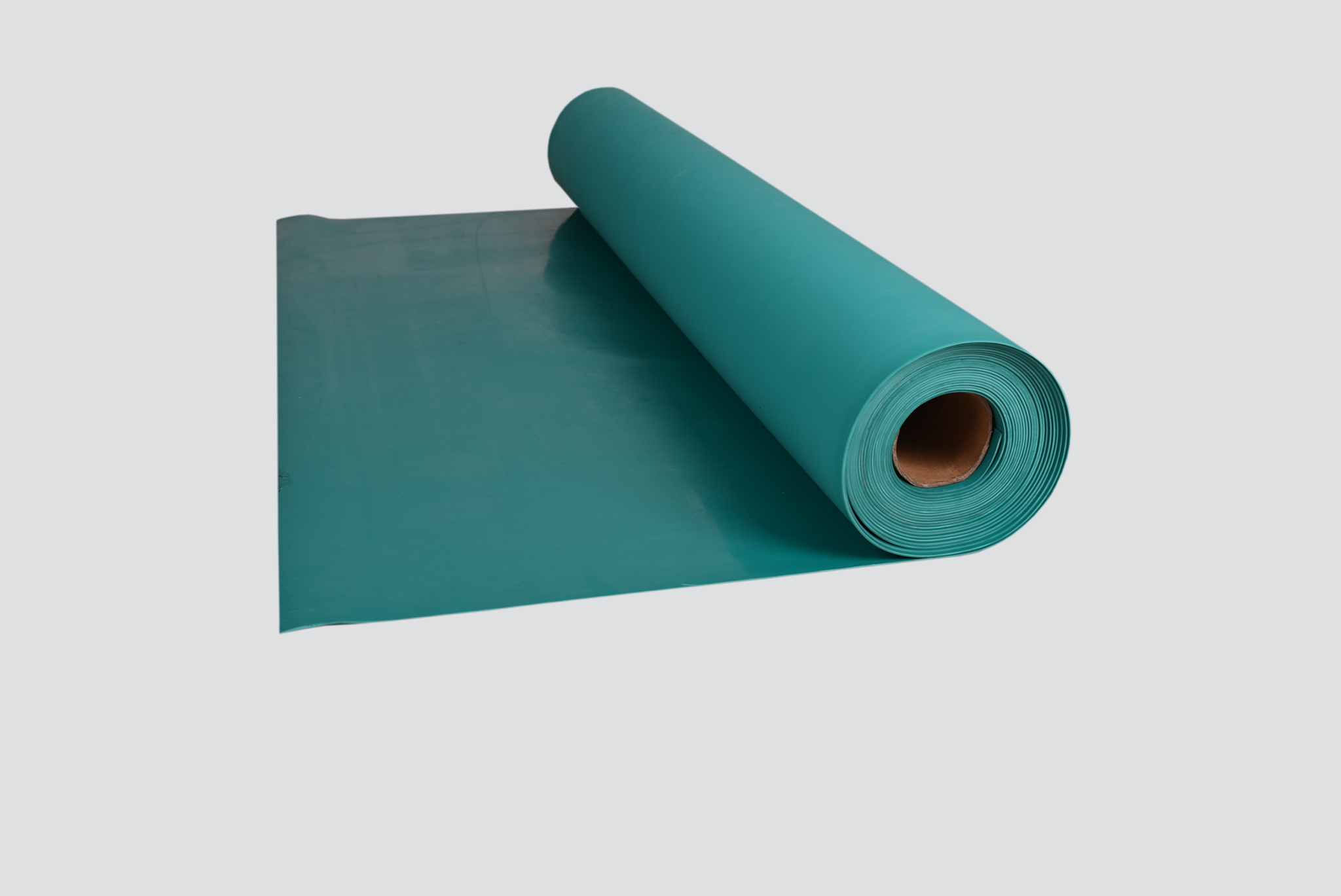

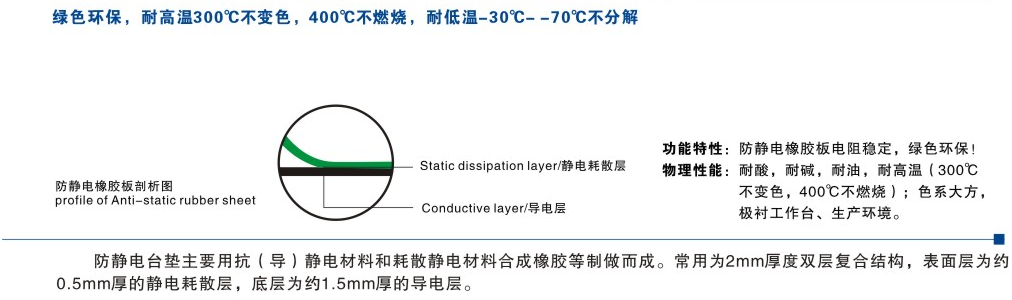

Green smooth environmental protection platform mat YY-A1016

The anti-static table mat is mainly made of anti-static (conductive) materials and dissipative static materials, synthetic rubber, etc. It is usually a 2mm thick double-layer composite structure, the surface layer is about 0.5mm thick electrostatic dissipation layer, and the bottom layer is about 1.5mm thick conductive layer.

technical parameter ? ? ? ? ? ? ? ? ? ?? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ??

| Common specifications ? ? ? ? ? ? ? ? ? ?? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

|

Friendly reminder: ? ? | It can be customized according to customer requirements (length, width, thickness, color, etc.). The company's anti-static rubber plate (table mat and floor mat) adopts pure high-quality rubber. We promise that it will never contain secondary rubber, waste rubber, recycled rubber and plastic. You can cut and proofing for free. The product has passed the SGS test, meets the ROHS standard, and the halogen meets the standard. |

Application of antistatic rubber plate |

? ? Static conductive and anti-static rubber plate (table mat and floor mat) is applicable to aerospace, national defense, coal mine, black powder, pyrotechnic, electric initiating explosive products, ammunition charging assembly, civil blasting equipment, fireworks and firecrackers, electronic components, electronic instruments and meters, liquefied petroleum gas tank station, electronic semi conductor devices, electronic computers Electrostatic conductive rubber plate, anti-static rubber plate floor and worktable are paved in the production workshop and warehouse of electronic communication equipment, integrated circuit microelectronics industry and other industries in order to eliminate the accumulation of static electricity in human body and environment and prevent static hazards and accidents. The function of paving static conductive and anti-static rubber plate (table mat, floor mat) ground and worktable is to effectively leak the static electricity on human body, tooling, equipment and materials into the ground and eliminate the static electricity harm to human body and environment. Prevent fire and explosion accidents caused by electrostatic discharge in the production site of flammable and explosive products; Prevent breakdown damage of components and finished components caused by electrostatic discharge in the production site of electronic products; Relieve the electrostatic shock and mental burden caused by electrostatic discharge. |

Laying of anti-static rubber plate |

? ?There are two laying methods of static conductive and anti-static rubber plates (table mat and floor mat), floating laying and pasting. Floating paving is to directly lay 2-5mm thick rubber plate on the ground, which is flexible and simple, but the gap at the joint of rubber plate is easy to accumulate dust. Pasting is to paste the 2-5mm thick rubber plate on the ground with electrostatic conductive rubber liquid. The gap at the joint of rubber plate can be 1.2x1000x10000mm thin rubber plate, cut into 30-50mm wide rubber strips with a paper cutter, brush and paste the electrostatic conductive rubber liquid on the gap surface at the joint of rubber plate. The straight edge of 5mm thick rubber plate can also be cut into positive and negative slopes with a paper cutter (or special cutter), roughened slightly, and coated with electrostatic conductive rubber solution for lap bonding. 1. The ground and rubber plate shall be free of dust, oil stain and moisture, and must be clean and dry; 2. Before pasting, clean the pasted surface with 120 ° gasoline, dry it, and then apply rubber liquid; 3. The ambient temperature shall be 25 ° c-42 ° C, and the relative humidity shall not be higher than 60%, which is generally good; 4. The adhesive surface of rubber plate shall be roughened slightly with coarse sand wheel, coarse sand paper, wood file, etc. (the edge of 30-50mm adhesive surface must be roughened); 5. The rubber liquid must be brushed twice on the pasted ground and rubber plate surface with a brush. The first time is dried for 20-30 minutes, and the second time is dried until it is slightly sticky; 6. If the rubber solution is too thick and inconvenient for construction, toluene can be added in the proportion of 10-20% of the rubber solution, diluted and stirred evenly before use 7. After the rubber plate is pasted on the ground, it shall be rolled with a round roller weighing more than 5kg for more than 5 times; 8. Pay attention to ventilation and fire prevention during construction; 9. During the use of rubber plate floor, if it is found that it is dehydrated and crimped due to mechanical operation, the above pasting method can be used for subsidy and repair. |

Resistance measurement of anti-static rubber plate ground |

The measuring instrument is an insulation resistance tester, with DC open circuit voltage of 500V and short-circuit current of 5mA. The measuring electrode is made of copper or stainless steel into a cylindrical standard electrode with a diameter of 60 ± 2mm and a weight of 2 ± 0.2kg. The measuring electrode must be treated against oxidation. 1. Place two measuring electrodes 1m apart on the ground, connect the two wiring terminals of the instrument with the electrodes respectively, and measure the resistance between the electrodes; 2. Place a measuring electrode on the ground, connect one terminal of the instrument with the electrode, and connect the other terminal to the grounding network of the workshop and warehouse (if there is no grounding network, it can be connected to the water filled tap water pipe), and measure the resistance to ground at this point; 3. At least 5 measuring points shall be selected for each workshop and warehouse. The measuring points shall be selected at the place where production workers operate and often walk, and shall be 1m away from the grounding body; 4. The arithmetic mean value shall be taken for both the inter electrode resistance value and the polar resistance value; 5. The ground resistance of electrostatic conductive rubber plate is ≤ 5x104 Ω or 5x104-106 Ω; The ground resistance value of anti-static rubber plate shall be in the range of 106 Ω - 109 Ω. |

Tel: 0576-87071888

0576-87071889

Mobile: 136 6168 8095

mail box:

zxl@zjyiyuan.cn

zj@zjyiyuan.com